Double Block and Bleed (DBB) valves have emerged as a critical safety component in the oil and gas pipeline industry. Designed to provide reliable isolation, these valves are widely installed across upstream, midstream, and downstream operations. Their ability to enhance operational safety and improve system integrity makes them a preferred choice for demanding applications in the petroleum sector.

What Are Double Block and Bleed Valves?

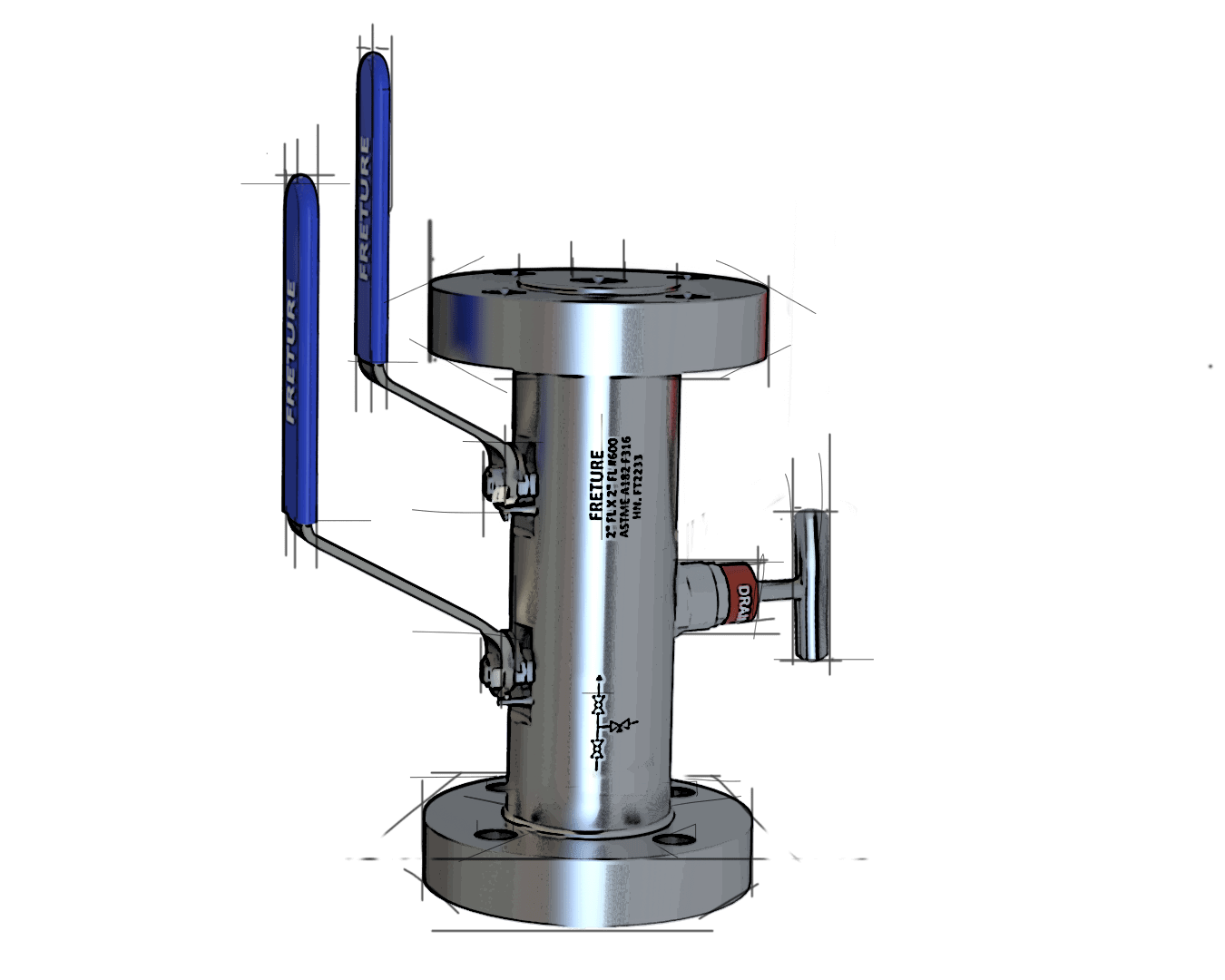

A Double Block and Bleed valve is a type of valve assembly that contains two separate sealing mechanisms and a bleed valve situated between them. It is engineered to isolate a process flow completely and allow for safe venting or bleeding of the trapped fluid from the space between the two sealing surfaces. This configuration ensures zero leakage and verifies isolation before maintenance or inspection work.

Functionality in Pipeline Systems

In oil and gas pipelines, the primary role of DBB valves is to guarantee isolation for maintenance or system modifications without interrupting the entire line. When both block valves are closed and the bleed valve is opened, any pressure or fluid trapped between the seals can be safely vented. This process confirms that there is no leakage past the first valve, adding a layer of protection for personnel and equipment.

Additionally, these valves are used during system pressure testing and purging operations. The design minimizes space, reduces weight compared to traditional two-valve setups, and simplifies installation, which contributes to more efficient system layout and operation.

Safety and Environmental Considerations

In the oil and gas industry, safety and environmental compliance are of paramount importance. The use of DBB valves significantly reduces the risk of unintentional product release, especially when working with hazardous or flammable substances. Their leak-tight sealing capability minimizes fugitive emissions, supporting environmental standards and reducing the risk of catastrophic failure during maintenance.

DBB valves are often used in emergency shutdown systems (ESD), where reliable isolation must be assured. In the event of a leak or fire hazard, these valves allow for sections of the pipeline to be quickly and safely isolated, preventing escalation.

Types of DBB Valves Used in Oil & Gas Pipelines

Different configurations of Double Block and Bleed valves are used in pipelines depending on the specific needs of the operation. Common types include:

Ball Type DBB Valves: Suitable for high-flow systems where tight shutoff is required.

- Plug Type DBB Valves: Used in situations demanding high pressure and temperature resistance.

- Gate Type DBB Valves: Preferred for pipelines where minimal pressure drop is critical.

- Each type is designed to meet industry-specific standards such as API 6D and ISO 14313, which ensures they can withstand high-pressure environments typically found in oil and gas fields.

- Applications Across the Pipeline Network

- DBB valves are widely deployed in various sections of the oil and gas pipeline network:

Pump and Compressor Stations: Used to isolate pumps for maintenance while keeping the line in operation.

Metering Skids: Installed to ensure accurate flow measurement and to isolate measurement devices during calibration.

Tank Farms: Prevent cross-contamination during loading and unloading operations.

Pig Launchers and Receivers: Enable safe insertion and retrieval of pipeline cleaning tools.

Their ability to prevent backflow, ensure zero leakage, and simplify maintenance activities has made them indispensable in every phase of oil and gas transport.

In oil and gas pipeline operations, safety, efficiency, and compliance are non-negotiable. The use of Double Block and Bleed valves supports all three by offering secure isolation, preventing fluid leakage, and ensuring system reliability. Their space-saving design, combined with operational flexibility, makes them an essential component in pipeline safety architecture.

When high-performance DBB valves are needed, choosing a reliable and experienced manufacturer ensures long-term value and peace of mind.